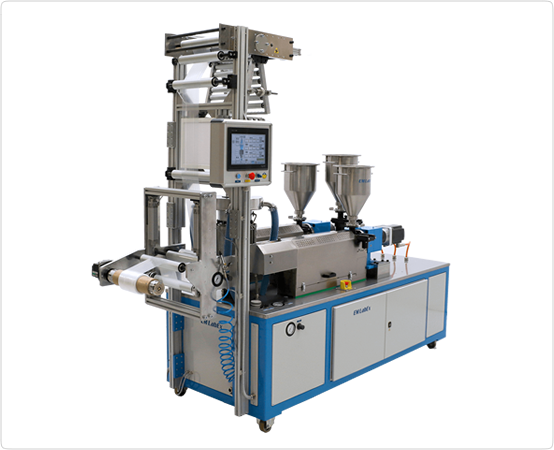

The EM LabEx 3 Layer lab extruder

Our 3 layer extruder machine features a compact design for testing and production of plastic films before large scale production. Therefore, your production can save a significant amount of time and money by ensuring quality film before large scale production.

This 3-layer lab extruder EM LabEx is ideal to test how different materials can be combined into one film.

- Compact Design

- Plug and play installation

- Operator friendly touch screen

- Easy programmable

- Quick and safe operation

- On wheels for easy transport

- Easy cleaning for fast change

- Low energy consumption

- Competitive price

Produce small webs of 3-layer tubular blown film and/or test any material for formula development, film blowing property test, master batch color dispersion test, optimization of blown film extrusion process parameters.

The lab extruder can process biodegradable and compostable bioplastics, recycled material, PE, LDPE, LLDPE, PP, masterbatch, plastic additives, as well as functional masterbatch.

Dimensions:

L: 2600

W: 880

H: 2100 mm (without tower extension)

Machine weight 950 kg (aprox.)

Documentation:

Electrical drawings

Operator Manual

Spare parts manual

EC declaration of conformity

The EM LabEx 3-layer extruder consists of:

Screen: Touch screen 12″. Easy to operate.

Frame: Robust steel frame with 4 wheels and adjustable legs.

Protection shields: Stainless steel protection around hot parts.

Hoppers: Stainless steel, easy empty system.

Barrel/die head Adaptor: 3 heater bands.

Temperatur control: Ceramic and cooling fans.

Barrel: 3 screws of high quality steel. Easy access for cleaning/replacement.

Drive units: 3 Screw motors.

Contact us for more information, press “Get a price”

A future-proof test Lab Extruder

Most plastic polymers are derived from fossil fuel-based chemicals like natural gas or petroleum. However, the demand for alternative polymers made of renewable materials as for instance plant derivatives is rising. Governments, consumers, and producers are turning towards more green and environmental friendly solutions when it comes to packaging and plastic products.

In this search for alternative polymers, film producers need to test the characteristics of these in the end film product. Of course it is necessary to produce a film that can provide at least same quality as the traditional formulas, and it is important to make the right choice when changing polymers.

The EM LabEx is designed to be able to test many sorts of plastic. The typical application of this test extruder is test of new polymers, bio-based plastic materials, recycled granules, 3-layer production samples, optimizing extrusion processes.

Having this machine in your production and a few kg’s of granule you can begin to test the material and immediately see the outcome. This text extruder can hereby save productions lots of energy, time and material.

You are welcome to contact us and inquire here.

Main Features

The EM LabEx 3 Layer

The EM LabEx 3 Layer

About the EM LabEx 3 Layer

The EM LabEx extruder is designed to be easy to use in order to start testing materials as quickly as possible, and the programming of the machine is very intuitive.

We develop reliable machines constructed from high quality mechanical parts and equipped with electrical components, PLC, and an operator terminal from Schneider Electric or Siemens. Furthermore, the software has been adjusted to meet our customers requirements for an easy operation of the machine.

Der EM-Laborextruder wird in Dänemark hergestellt und entwickelt. Jedes Teil ist sorgfältig ausgewählt und hat eine klare Mission: unsere Maschine in die Lage zu versetzen, möglichst viele derzeit und in Zukunft verfügbare Materialien wie z. B. Bio-Polymere zu testen.

Der EM-Laborextruder wird in Dänemark hergestellt und entwickelt. Jedes Teil ist sorgfältig ausgewählt und hat eine klare Mission: unsere Maschine in die Lage zu versetzen, möglichst viele derzeit und in Zukunft verfügbare Materialien wie z. B. Bio-Polymere zu testen.